PRODOTTI

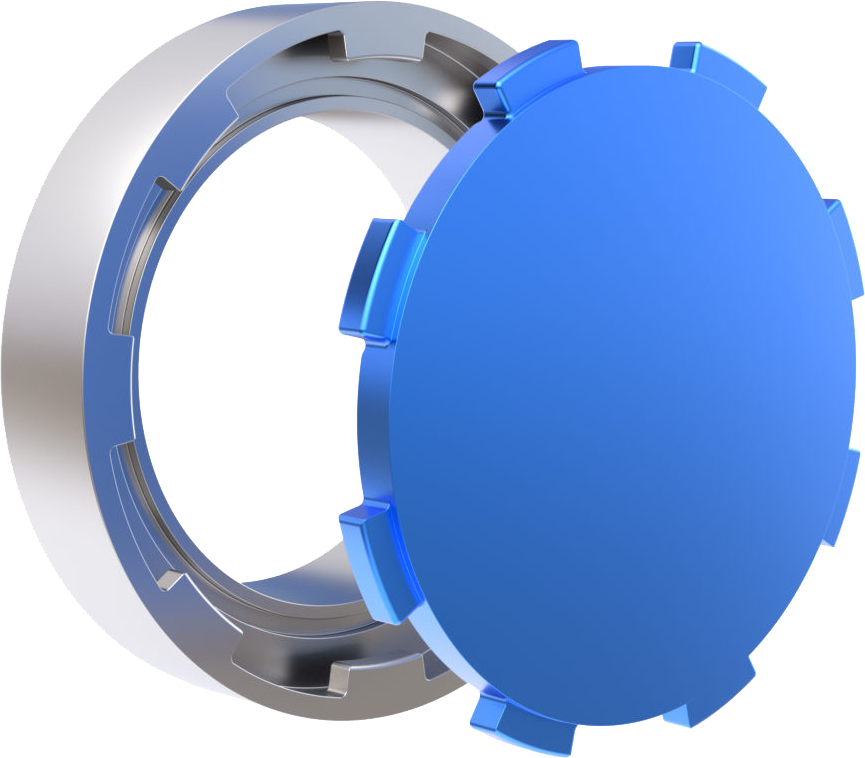

Le chiusure rapide a denti di QOC Solutions sono disponibili sia in versione manuale sia automatica. La QOC a denti si aziona attraverso un sistema di incastro a denti che ruotando ne consente l’apertura. La rotazione manuale è basata su un sistema a cremagliera; in caso di chiusura rapida automatica la rotazione si basa su un sistema composto da pistoni e pompa idraulici.

Per le QOC a denti consigliamo dimensioni comprese tra DN 6’’ e DN 46’’.

Il rating particolarmente consigliato è ANSI 150, ma la tipologia è applicabile fino a rating ANSI 600.

| Product Information | |

| QOC Nominal Size | From 6″ to 46″ |

| QOC Design Code | ASME VIII Div. 1 / Div. 2 / EN 13445 |

| QOC Design Pressure Rating | Up to ANSI 600 |

| QOC Design Temperature (min/max) | -46°C / +350°C |

| Qoc Orientation | Horizontal/Vertical |

| Gasket Seal | Lip seal |

| Design Conditions | |

| Design Code ASME VIII Div. 1 | Yes |

| Code stamped |

|

| Vassel Wall Thickness | Acc. to the vessel |

| Vessel PWHT |

|

| NACE Compliance (MR0175/ISO15156) |

|

| Principal Materials | |

| Hub Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

| Door Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

| Gasket Seal | NBR/HNBR/VITON/KALREZ |

| Hinge/Davit Material | Carbon Steel / Stainless Steel |

| Pressure Warning Screw Material | Stainless Steel |

| Pressure Warning Screw Seal Material | HNBR |

| Certification | |

| Material Certification | Acc. to EN 10204 2.2/ 3.1/3.2 |

| Non-Destructive Testing | |

| M.P.I. On Weld End Preparation |

|

| Dye Penetrant onWeld End Preparation |

|

| Ultrasonic Examination | Yes |

| Other Requirements | |

| Inspection Requirements |

|

| ASME U/U2 – Stamp Partial |

|

| CE Marking |

|

| Finish rough machined | |

| Finish (std) | Sandblasted and coated with zinc rich epoxy primer |

| Weld Overlay Material |

|

| Nickel plating |

|

| Final painting according to specification |

|

| Cold galvanizing | N.A. |

| Teflon coating | N.A. |

| Mechanical Key Interlock |

|

*![]() = APPLICABLE AT REQUEST

= APPLICABLE AT REQUEST

| Product Information | |

| QOC Nominal Size | From 6″ to 46″ |

| QOC Design Code | ASME VIII Div. 1 / Div. 2 / EN 13445 |

| QOC Design Pressure Rating | Up to ANSI 600 |

| QOC Design Temperature (min/max) | -46°C / +350°C |

| Qoc Orientation | Horizontal/Vertical |

| Gasket Seal | Lip seal |

| Design Conditions | |

| Design Code ASME VIII Div. 1 | Yes |

| Code stamped |

|

| Vassel Wall Thickness | Acc. to the vessel |

| Vessel PWHT |

|

| NACE Compliance (MR0175/ISO15156) |

|

| Principal Materials | |

| Hub Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

| Door Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

| Gasket Seal | NBR/HNBR/VITON/KALREZ |

| Hinge/Davit Material | Carbon Steel / Stainless Steel |

| Pressure Warning Screw Material | Stainless Steel |

| Pressure Warning Screw Seal Material | HNBR |

| Certification | |

| Material Certification | Acc. to EN 10204 2.2/ 3.1/3.2 |

| Non-Destructive Testing | |

| M.P.I. On Weld End Preparation |

|

| Dye Penetrant onWeld End Preparation |

|

| Ultrasonic Examination | Yes |

| Other Requirements | |

| Inspection Requirements |

|

| ASME U/U2 – Stamp Partial |

|

| CE Marking |

|

| Finish rough machined | |

| Finish (std) | Sandblasted and coated with zinc rich epoxy primer |

| Weld Overlay Material |

|

| Nickel plating |

|

| Final painting according to specification |

|

| Cold galvanizing | N.A. |

| Teflon coating | N.A. |

| Mechanical Key Interlock |

|

*![]() = APPLICABLE AT REQUEST

= APPLICABLE AT REQUEST